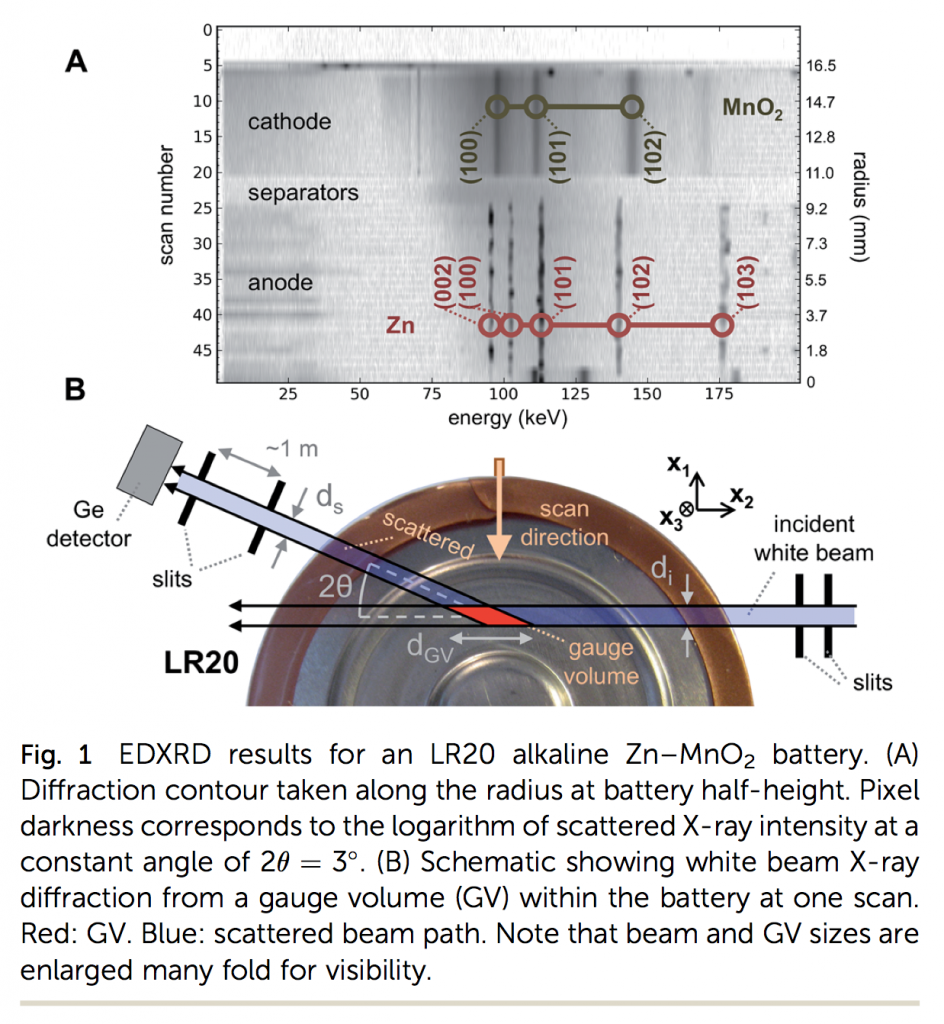

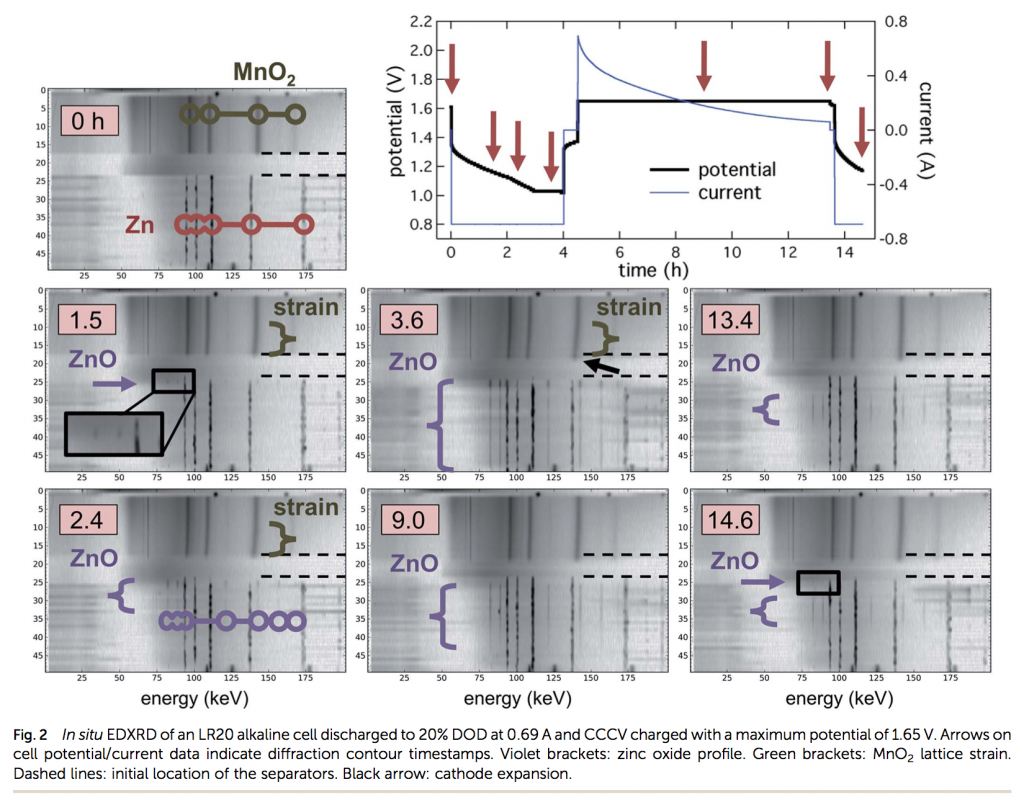

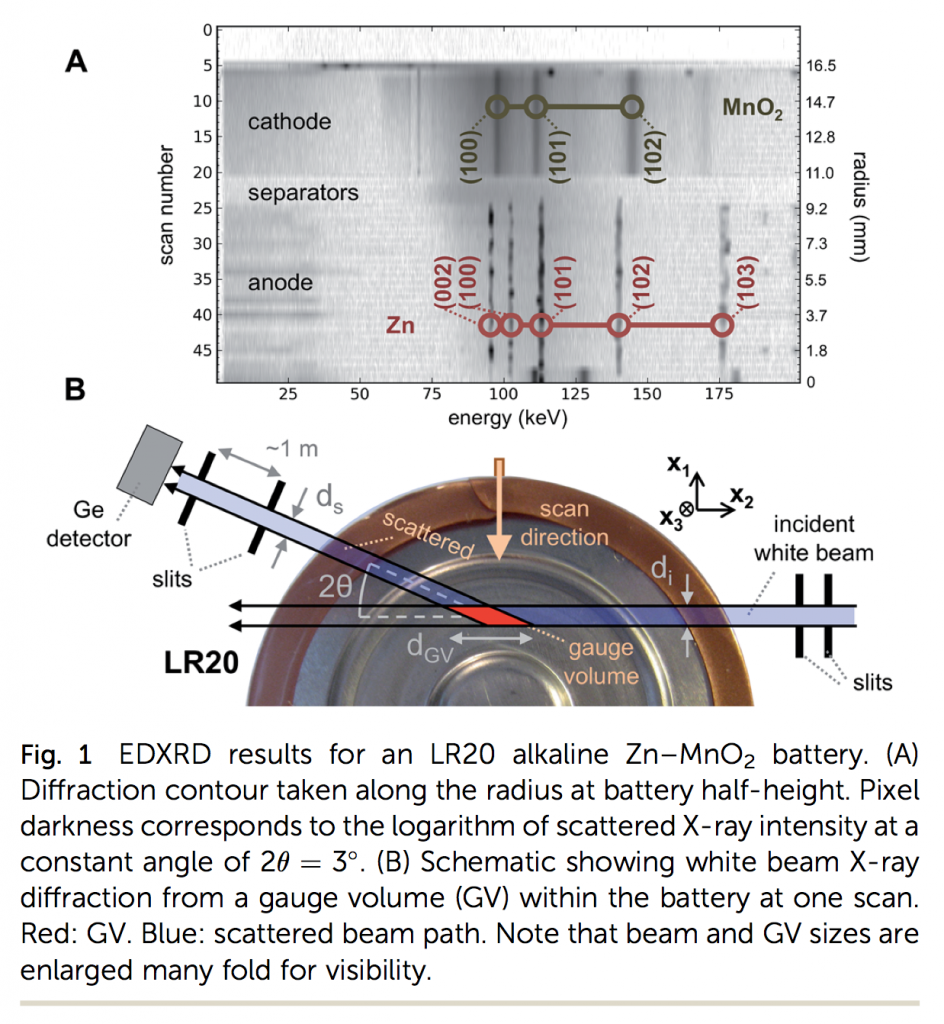

We just had a paper published in The Journal of Materials Chemistry A about some research done at Brookhaven National Lab. It’s cool and new because it uses extremely high-power X-rays that can penetrate thick materials, even metals. The technique was developed to find points of strain inside high-performance materials like turbine blades. We use it to do the same thing, but inside batteries. And not just small batteries, but very thick ones, like D-cell batteries, which are an inch or two across.

We just had a paper published in The Journal of Materials Chemistry A about some research done at Brookhaven National Lab. It’s cool and new because it uses extremely high-power X-rays that can penetrate thick materials, even metals. The technique was developed to find points of strain inside high-performance materials like turbine blades. We use it to do the same thing, but inside batteries. And not just small batteries, but very thick ones, like D-cell batteries, which are an inch or two across.

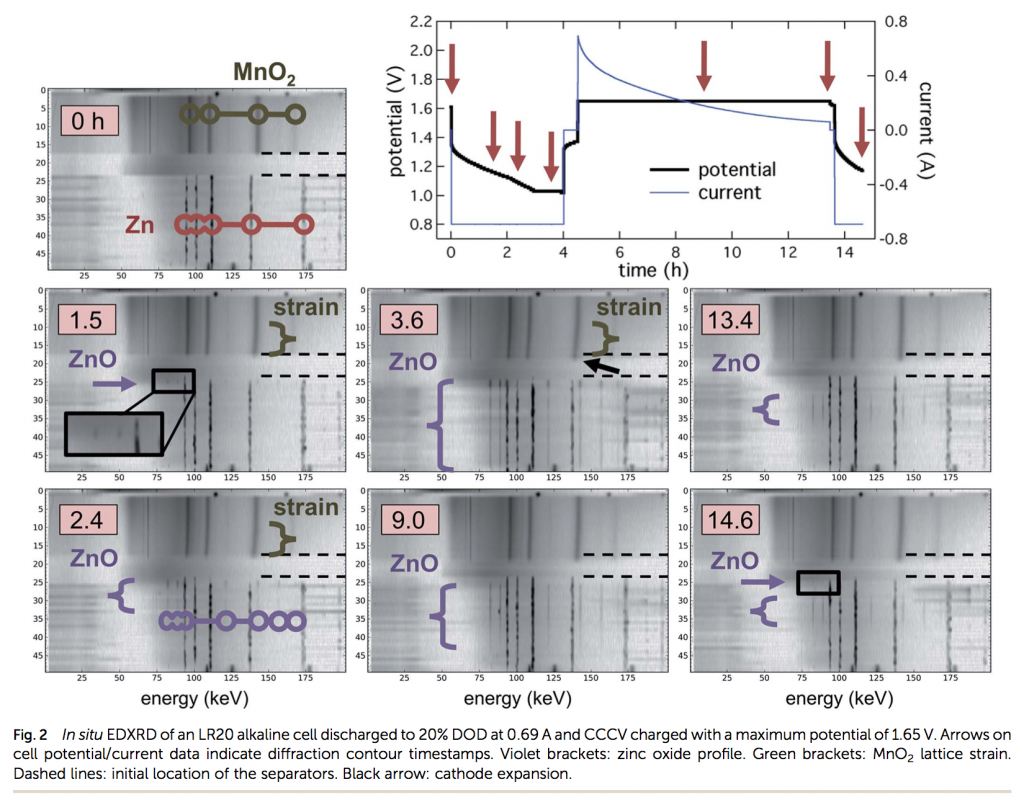

Inside the battery, the X-rays bounce off crystal faces of the materials, and because of that you can know things about how far apart the atoms are. A D-cell has zinc at its center (anode) and manganese dioxide around its outside (cathode). The lines in the image above are like fingerprints of these materials. (And the numbers like (002) refer to the crystal faces themselves.)

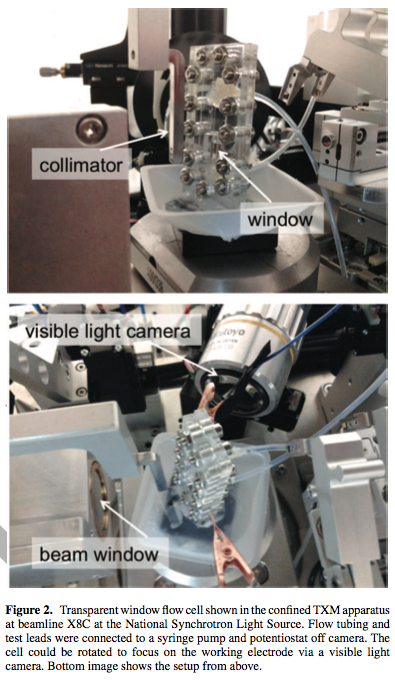

Another cool thing about this technique is that it is very fast. You can scan the battery in a few minutes. This means that as it’s charging and discharging you can watch the materials changing in real time, inside the sealed battery. Basically this is what we do in the paper, shown below, seeing some things no one has ever been able to see before (except by cracking a battery open after cycling it, which can sometimes be effective, but not always). Brookhaven (on Long Island, in New York) is one of the only places in the world you can do this.

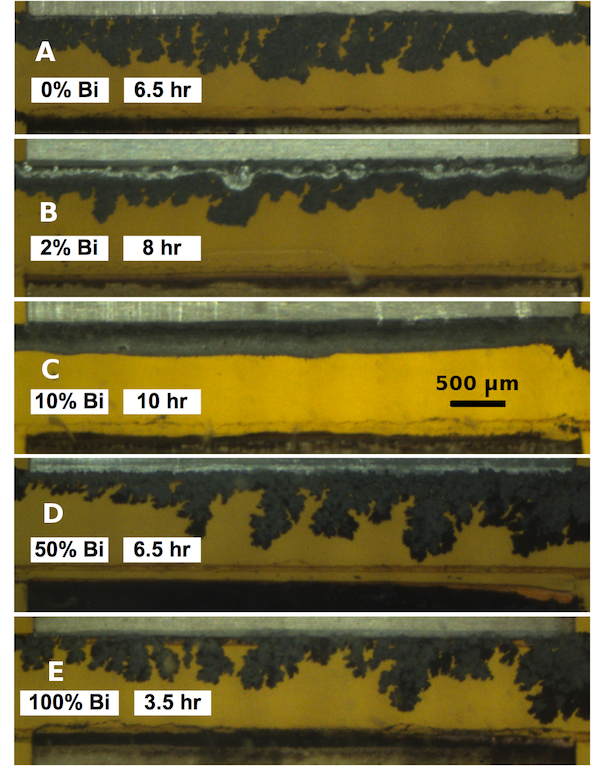

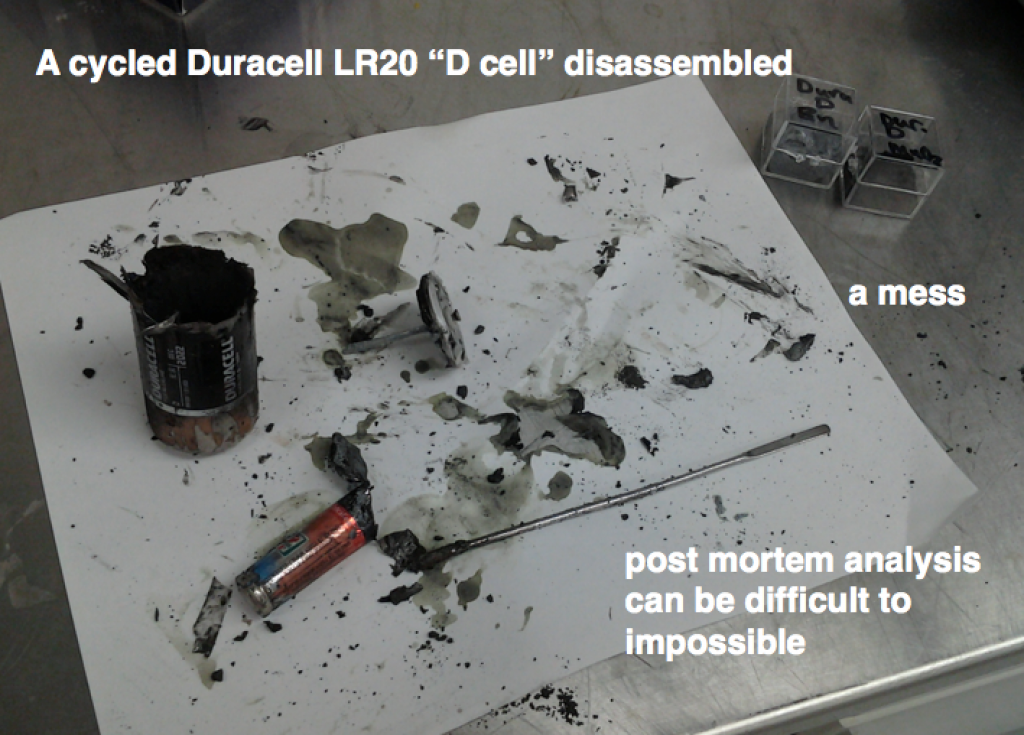

I was looking though some research photos and I found this nice example of why post mortem battery analysis is better done by some X-ray technique. Once you start opening things up, you mix the materials around, you oxidize them, etc, unless you have a very good method, which is probably tedious.

I was looking though some research photos and I found this nice example of why post mortem battery analysis is better done by some X-ray technique. Once you start opening things up, you mix the materials around, you oxidize them, etc, unless you have a very good method, which is probably tedious.