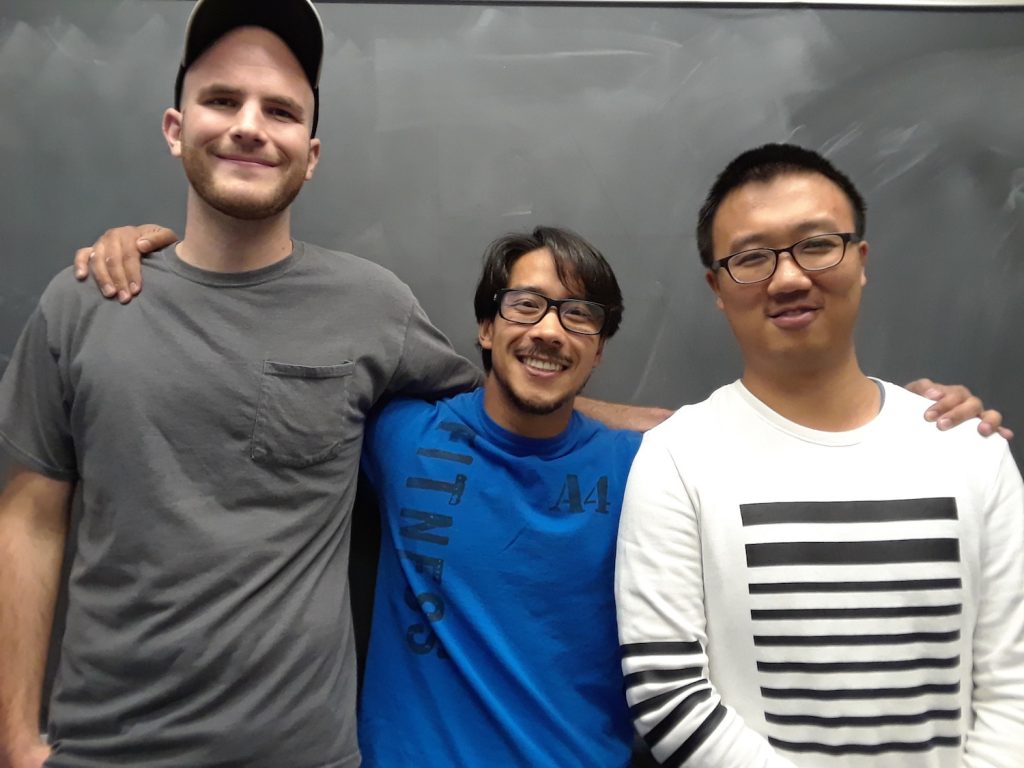

Introducing our lab group, seen here at our second ever Friday afternoon group meeting. From left to right, Ben Howell, Matthew Kim, and Zhicheng Lu. All devouring electrochemistry and coming up to speed. The future is truly bright.

I’ve been mulling over what to call the group. “Gallaway Group” would be fine, but as is the fashion these days perhaps it should be something both punchier and more descriptive, with an acronym involved. The Complex Electrochemical Systems Lab (CESL, pronounced “sessil” if you like) is what told Northeastern I might do before I got here, so maybe that’s it. What do I mean by complex? All electrochemistry is complex from a certain point of view. But here I specifically mean systems when multiple phenomena are important throughout the regime of operation, such as two kinds of diffusion (e.g. in a solid crystal and in an electrolyte) or three kinds of kinetics (e.g. both substrate and mediator of an enzyme, also with mediator electrode kinetics). To that you could say “That means all real battery or fuel cell systems are complex.” To which I would say “Yes that’s right.” But this is a defined viewpoint, a worldview, and those are good to set down for all to see. It tells you we will always be trying to break down a complex system, and then build it back up … engineered to be better of course.